A not infrequent scenario in certain parts of the country: A customer brings a recently purchased bike to a shop to have a wheel trued and is dismayed to learn that the spoke nipples are seized and the wheel needs to be rebuilt. The customer may be understandably upset–How can this happen on a brand new set of wheels? Why haven’t I haven’t experienced the same problem with other wheels?

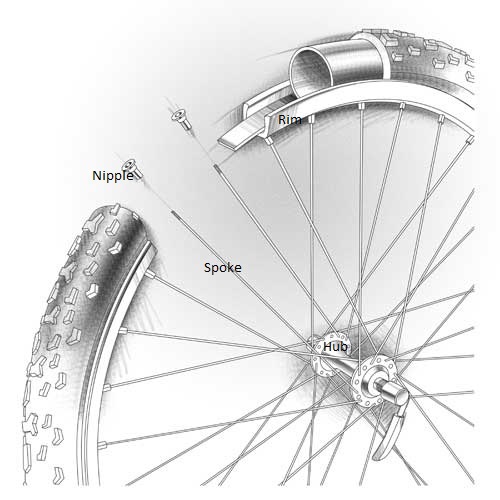

The answer is at once straightforward and complicated. A wheel consists of a hub, spokes, and rim. The spokes are threaded into “nipples,” small nuts anchored at the rim. (A few wheels have the nipples at the hub.)

Spokes are typically made out of steel and nipples are made out of brass or aluminum. When dissimilar metals or metal alloys come into electrical contact galvanic corrosion occurs: One metal corrodes and deposits residue on the other, causing the nipple and spoke to essentially fuse. That’s the straightforward answer. The complicated answer has to do with how the wheels are built and the climate in which they are ridden.

Wheels built with brass nipples generally don’t corrode. Brass and steel have similar relative voltages (only .10v difference) so not much electrical activity goes on. Many modern high performance wheels, however, use aluminum nipples because they are lighter than brass. Aluminum, however, has a .5volt difference from steel, which means a high likelihood of corrosion when the spoke and nipple come into contact with brackish water which contains the electrolytes necessary for galvanic corrosion to occur. Corrosion is rampant in coastal towns and in Northern states where roads are salted during the winter.

To inhibit corrosion, most high quality wheels are built with “spoke prep,” an enamel like material between spoke and nipple that prevents electrical contact. Spoke prep also creates friction which prevents the spokes from unthreading. Unfortunately, the prep slowly breaks down over time and will no longer provide protection. Further, high tension wheels often use a brittle prep (such as locktite), which reduces the chance of spokes loosening, but will disintegrate when nipples are turned during truing. Once the spoke prep has disintegrated, corrosion is inevitable unless the wheels are subsequently maintained.

Spoke nipples need to be lubricated EVERY time a rider is caught in the rain and probably once every month or two, irrespective of the weather. A petroleum based oil will displace water and prevent corrosion.

As illustrated by Durham Cycles’ customer Lee Sandstead, simply place a single drop of lubricant on the spoke where it enters the nipple. A lightweight chain lube will penetrate the nipple well, coating all the threads. Even if you don’t see it happen, you are likely to get some lubricant on your rims–it is VERY important that you wipe the braking surface with a clean rag, then clean with alcohol until you are confident no residue remains.

That’s it for now. Remember, email your questions to us through the contact page or send us a note on Facebook.